1914 10F update

The 10F is making steady progress. Almost complete now, it’s been a few years since she first hit the bench.

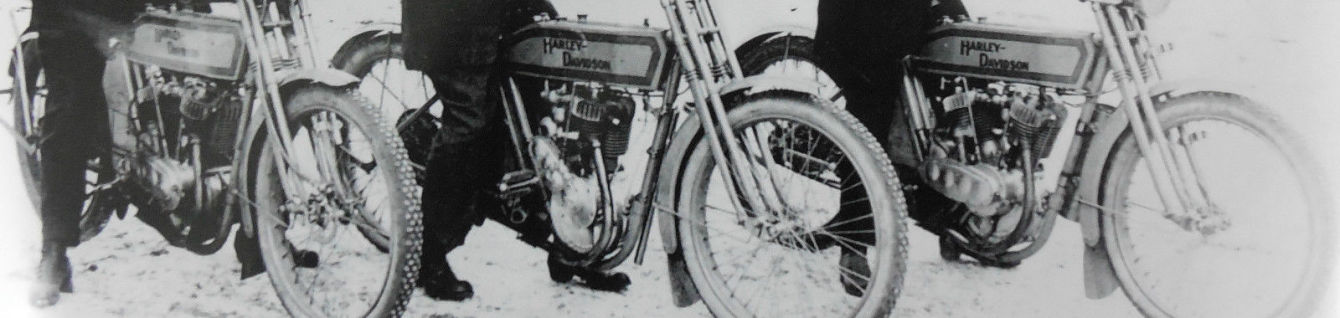

SINGLE SPEED HARLEY DAVIDSON MOTORCYCLES

The 10F is making steady progress. Almost complete now, it’s been a few years since she first hit the bench.

Out in the cornfields testing the 9B earlier in the week. I have 60 psi compression but I think that is too low. It only converts to just over 30mph on the road and we need more than that.

After reading the last post I realised that I haven’t put up any photos of the completed 8XE. I‘m pleased with the outcome. She is an up and running motorcycle now, some six or seven years after I got her.

The paint finish is with broad black striping, edged in carmine, and with a gold centre pinstripe. I just need to find a source for some white rubber pedal blocks.

The 8XE is finished now and work on the 10F is well underway so I thought I’d try something different before I start on the 8D.

l always struggle to find a regular daily rider that I’m happy with and the reason is that I always end up compromising between functionality and having a ‘cool’ style.

This is a late 51 with a hand clutch, 12 volt, belt drive and a super E carb. Trouble is it also has awful disc brakes and crappy style.

I’m going to replace the brakes, Bob it with 19 front and 18 rear wheels, lose some of the chopper look and add a little style. I might add an Ebeyond ignition and a luggage rack!!

The magneto came back from the painter and we have installed it on the bike. Some time spent making adjustments and she is now finally up and running.

When the Coronavirus lockdown is over we will take her out for a few miles and get her dialled in and sort out any other niggles. For sure we need to look at the rim on the rear wheel.

Stay safe everyone.

SOLD

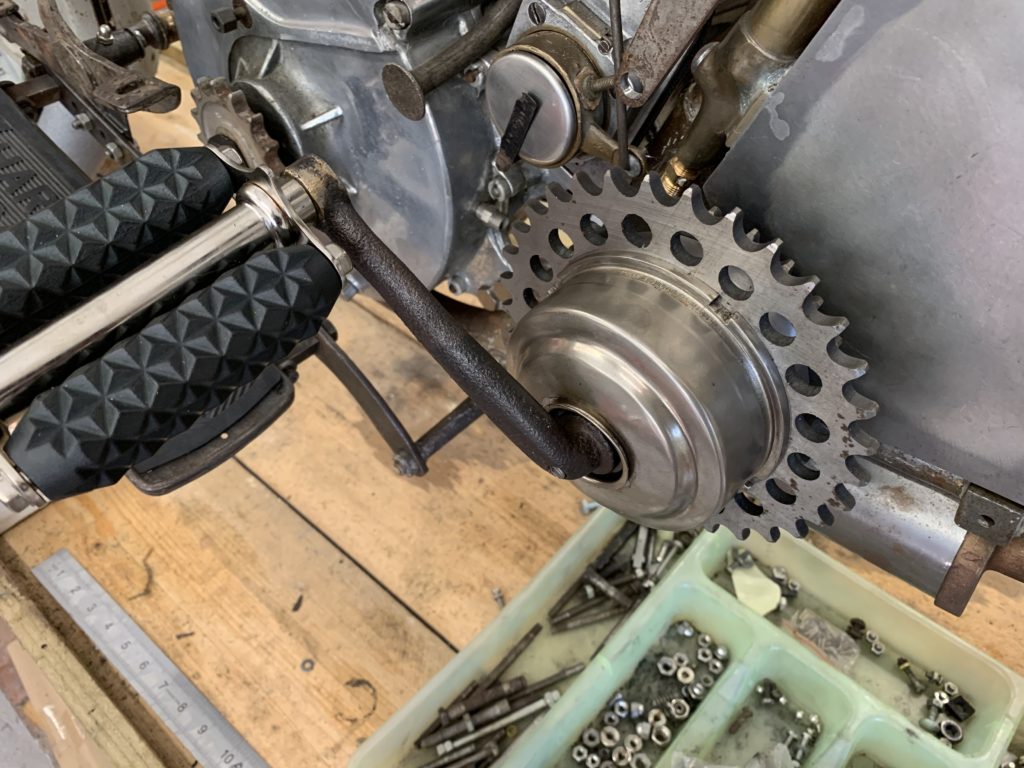

The pedalling gear is all sorted and fitted now. The cranks and internal parts all came with the project. The sprockets needed some work to fit and we needed to fabricate a few small parts.

The pedals came from Aaron Mohr and the brake actuating rods from Jethro Smith. Next is the build of the rear wheel.

The 9B seemed to be lacking power recently so we decided to double check all the timing; that is for the exhaust and inlet valves, and the ignition.

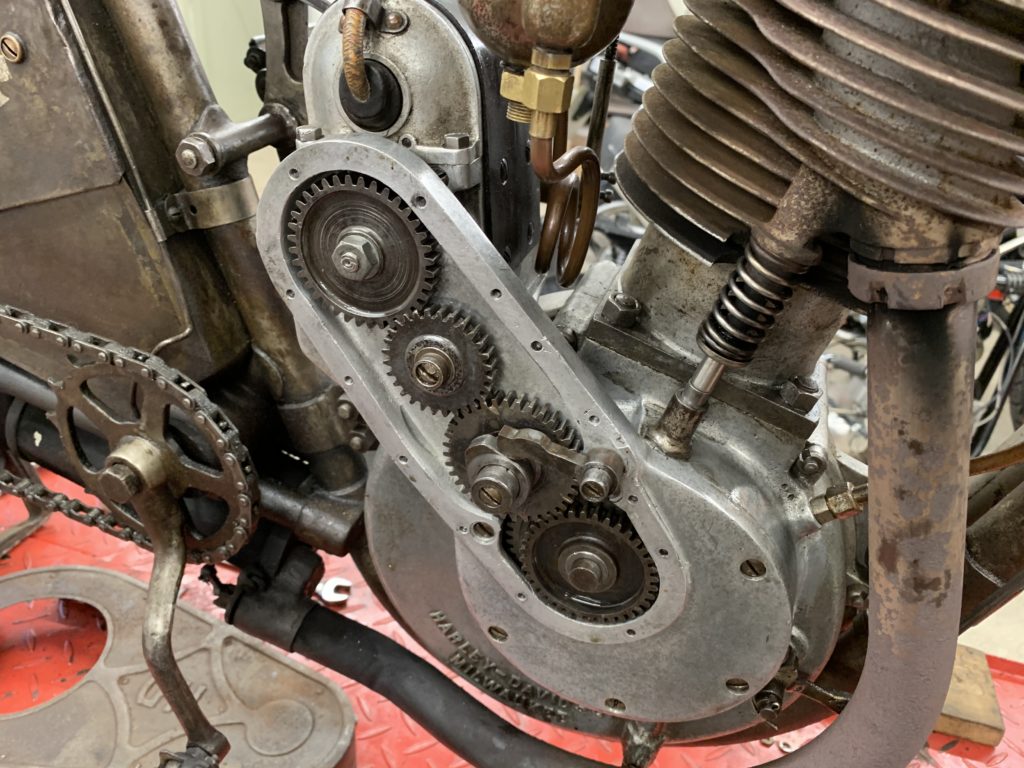

First, remove the timing cover and then the magneto perch, complete with magneto. The exhaust valve operates via a cam on (behind) the larger gear wheel which is not visible when the magneto cover is still in place. The valve closes when the piston is 1/32” to 3/32” after top dead centre. The piston is visible when you remove the inlet valve tower.

With the exhaust valve done, the next gear wheel operates the inlet valve. Refit the cover and the pushrod to set the timing such that the valve opens 3/16” before the piston reaches TDC.

Then refit the intermediate and the magneto gears. The ignition should be set so that the breaker points are just separating at 3/16” – 1/4” before TDC on the compression stroke. Then the inlet pushrod and the timing cover need to be refitted, as well as the inlet valve tower. Job done, we now need to wait for some decent weather to do a test run.

A couple of notes; first we removed the front chain cover and turned the motor by hand with a wrench rather than by turning the rear wheel, and second TDC. The book says the way to determine TDC is to remove the motor from the frame and check the piston by looking through the top motor plug. Well that’s a lot of extra work so we went in through the inlet valve tower……they say not to do it that way!